By Jeremy Kichler, Bill Starr, Sarah Beth Thompson, Wesley Porter

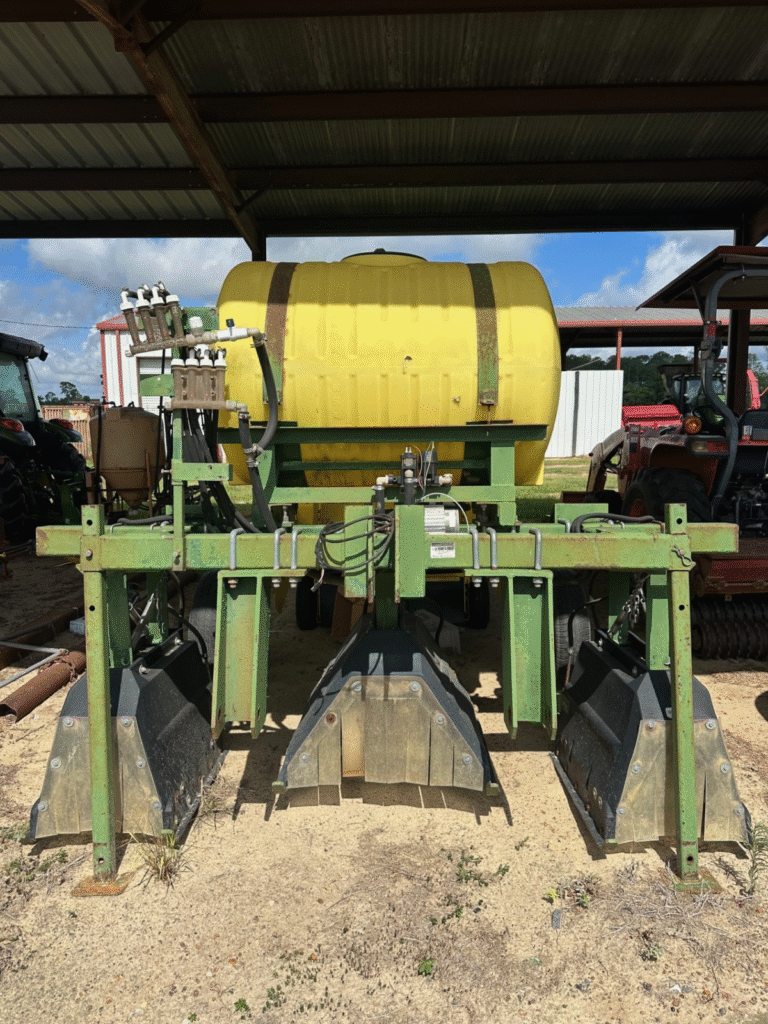

Due to the nature of how they work and the area they are covering, hooded sprayers can be confusing and difficult to calibrate. You can over-simplify or over-complicate the calibration procedures as you work through them. Since there are multiple nozzles under the hood and directed spray nozzles (or banded spray nozzles) associated with the hooded sprayer that can be sprayed simultaneously it is critical that careful consideration is taken when performing a calibration on this system. It is also necessary to emphasize that hooded sprayers cannot and should not be operated at the same speeds as our boom sprayers. We should target at or under 5 mph. Thus, for my examples below I have used 5 mph.

What is tricky is that you have multiple nozzles spraying under the hood and multiple nozzles outside of the hoood and each one may not necessarily be covering the same area. Hopefully, we can assume the area each of the nozzles under the hood is the same and that the two banded nozzles outside of the hood is the same. Thus, the first and most important part is that the entire calibration is performed based on the spray area for the total area covered by all nozzles under the hood, and the banded nozzles outside the hood separately. This is because in some cases a grower may decide to spray one rate and chemical with the hood while he is spraying something else at a different rate with the banded under the crop canopy outside of the hood. Based on manufacturer’s recommendations for hooded sprayers, the same nozzle should be used across all nozzles on the hooded sprayer.

Calibration Steps

Banded Nozzles

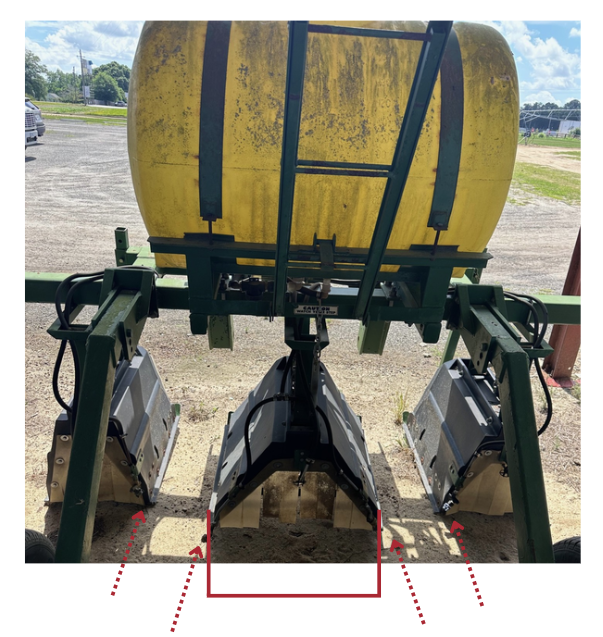

First measure the total width of the hood. In most cases hoods will be around 28 to 30 inches wide. Since someone asked me about a 28-inch-wide hooded sprayer we will use this as an example. Next, based on your row width, with 36” being common in most of our areas, we can assume that our two banded nozzles are covering 8” total (or 4” on each side of the hood).

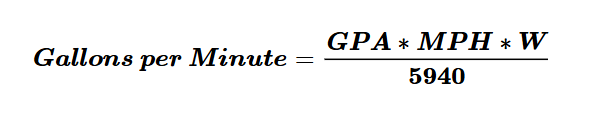

Going back to the sprayer calibration post at Sprayer Calibration | Extension Precision Ag and Irrigation, you can use the same formula and methods for calibration.

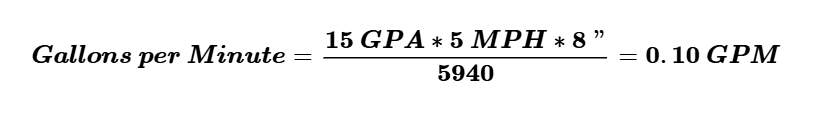

From our numbers above, we are banding across a total of 8 inches or 4 inches per nozzle. You should catch each nozzle individually, but you can calculate it either as 4” per nozzle or 8” total width depending on how you want to perform the calculation. Doing an individual nozzle catch is preferred as it allows you to check uniformity of nozzles. Let’s assume you want to apply for a 15 GPA rate. Use the formula below to determine your catch for the two nozzles combined and for each one individually.

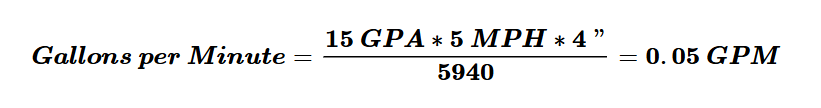

For the total coverage area of the banded nozzles:

For each individual banded nozzle:

Under the Hood

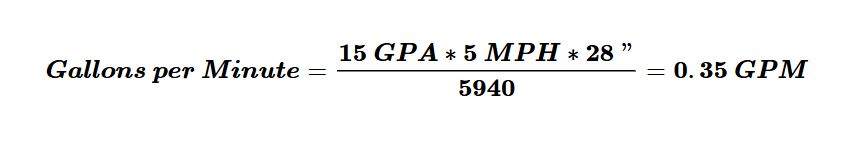

Next we need to work on calibrating the nozzles under the hood. Theoretically, this should be a different pump, tank, and valves from the banded nozzles. From our previous numbers we know that the hood is 28” wide, and let’s assume similarly we want to apply 15 GPS, thus we need to catch an equivalent flow rate for 15 GPA. Using the same formula with the new width:

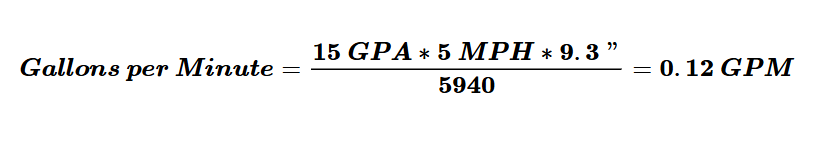

Now if we wanted to check individual nozzles under the hood we assume that the width is uniform, so they all will be covering 9.3 inches. Using the same formula again, for the reduced width:

Just to verify, 0.12 times 3 for the three nozzles is 0.36, due to rounding error it’s 0.1 GPM too high, but let’s be honest and say that is the same as the 0.35 GPM calculated earlier.

Now, to complicate things further, let’s assume that one tank is feeding all 5 nozzles!! If this is the case, you still need to do your best to calibrate each one individually. You can start with either the band or the hood. However, you will need to, against manufacturers’ recommendations, change nozzles and/or orifices in the nozzles to achieve target rates. Just to put it into perspective from our earlier example. We are covering 28” with the hood and 8” with the band. The hood covers 78% of the width and the band covers 22% of the width. So, you will need to reduce your flow from the band to the nozzles by this proportion. This can be achieved by using smaller orifices and/or nozzles proportional to the flow rate of the nozzles under the hood. Unfortunately, it probably will not be possible to achieve the exact targeted rate, so you will need to get one of the two calibrated and then get as close as possible with the other nozzles.

The task of calibrating a hooded sprayer can seem daunting even if you have done it before. My biggest suggestion is for you to work through it one step at a time and don’t get ahead of yourself. If you have further questions or need more assistance with hooded sprayer calibration, reach out to your UGA County Extension Agent. This process can be complicated, but if you break it down and take your time, it can also be straightforward.