By: Phillip Edwards, Daniel Lyon, David Hall, Jason Mallard, Sarah Beth Thompson, Wesley Porter

Pivot Uniformity

The importance of proper pivot uniformity cannot and should not be taken lightly. Over or underwatering your crop can happen due to a multitude of possible inefficiencies. These inefficiencies can cost you money and yield. In most cases you may not even notice any visible issues or concerns. If you want to get your pivot in good working order a good start would be contacting your county Extension office. With the help of your county agent and assistance from the UGA Extension Ag Water Team, a pivot uniformity test can be conducted. We call them Mobile Irrigation Labs (MIL) because we will come out to your pivot and make a pivot uniformity assessment. It is a relatively simple process and though it takes a little time, the results will help in getting your irrigation system to function in an efficient manner. The picture below shows a pivot irrigating corn in which visible dry streaks can be observed in the field where the overlap between nozzles is not correct. I can promise that these streaks will continue to show up throughout the entire season and will show up on a yield map of the field at the end of the season. The farmer was surprised and upset when he was able to get this aerial view of his field. He also knew that he was too late to fix this issue this late in the season. Luckily, in this case he found that the wrong pads were installed in the nozzles and swapping them would fix his issue. This was a simpler and quicker fix compared to other issues that are seen during the production season. The last place that you want to observe irrigation uniformity and application issues is on a yield map. Thus, it is imperative that you make a plan to evaluate pivots on a regular basis. Depending on water quality and source, irrigation nozzles need to be replaced approximately every 5 to 10 years.

Cost of Irrigation

According to the 2025 Crop Comparison Tool (https://agecon.uga.edu/extension/budgets.html) variable cost per acre to apply irrigation in conventional tillage ranges from $40-80 per acre ($30-70 in strip-tillage) depending on the crop. There are also fixed costs which are calculated at $140 per acre and not crop dependent. We tend to think of seed, fertilizer, and chemical cost as our largest expenditure, however if you consider both the variable and fixed irrigation costs together, it shows that total irrigation cost is one of the most expensive expenditures in your farming operation each year.

Mobile Irrigation Lab

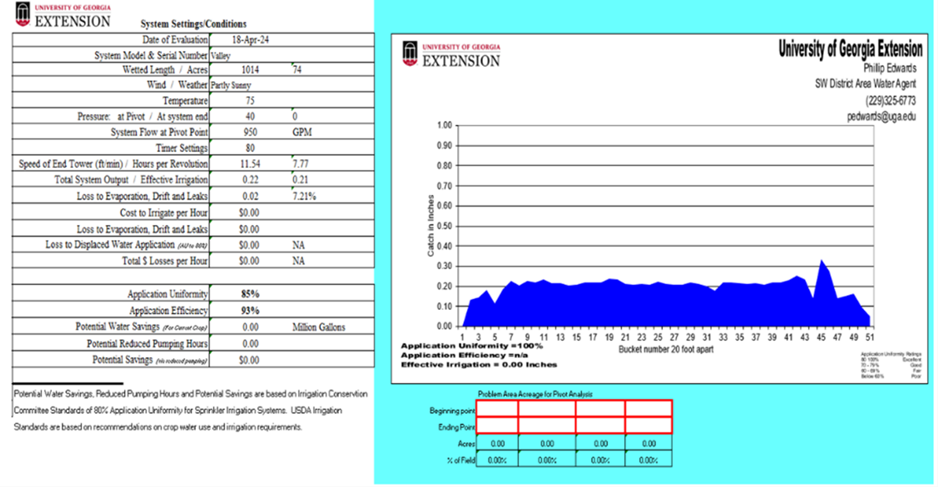

Conducting a MIL is free and can be requested by the county extension agent. Although it is recommended that pivot audits are completed in the winter when systems aren’t operating regularly, a MIL can be conducted any time during the year if the situation is critical and especially if chemigation or fertigation is going to be used. It is preferable to have clear skies, minimal wind and a grass waterway or open area where we can run the pivot over the measuring buckets. If you choose to do a MIL, then your pivots will be audited to show application uniformly, end gun performance, system flowrate, and malfunctioning nozzles. We will even be able to supply an updated application chart based on the current system performance. The entire process of an MIL can be found here: Evaluating and Interpreting Application Uniformity of Center Pivot Irrigation Systems. An MIL is completed by placing buckets across the length of the pivot to capture water as the pivot moves across them applying a standard and know rate of irrigation.

After the pivot has passed over all of the buckets pour the water into a graduated cylinder so that you can measure the amount of irrigation that was applied. Record this amount to the appropriate location on a sheet so that you can determine the application rates along the length of the pivot.

Use a flow meter to determine the total flow of the system. Water sources should have an operating flow meter attached to them. If a farmer wants to verify an existing flowmeter an ultrasonic one is available through the UGA Extension Ag Water team.

Once the MIL is completed a uniformity chart along with system parameters will be created and provided to the producer. The uniformity levels that are observed will fall into one of the following categories:

- 90 to 100 — Excellent; no changes required.

- 85 to 90 — Good; no changes required unless a problem area is obvious.

- 80 to 85 — Fair; no improvements needed but the system should be monitored closely.

- Below 80 — Poor; improvements needed, particularly if chemicals are to be injected.

The chart created will now provide producers with a new pivot application calibration chart and an uniformity chart for their pivots. This chart will allow them to correct areas that are either over or under applying irrigation.

Some of the common problems of poor uniformity/potential repairs are as follows:

- Clogged nozzles/Remove and clean nozzles.

- Sprinklers not turning/Repair sprinklers.

- Inadequate system pressure/Increase pressure if possible. Ensure that the correct gallons per minute (gpm) are flowing.

- Elevation differences/Pressure regulators may be required.

- Sprinkler in wrong order/Obtain computer printout from manufacturer and install sprinklers correctly.

- End gun not adjusted properly/Adjust part circle stops on end gun. Refer to the CID sheet for correct angles.

- Wrong end gun nozzle/Place correct nozzle on end gun.

- Worn nozzles Replace sprinkler nozzles.

- Excessive water in cup/Look for possibility of water “channeling” down pivot support structure or a leak at that location.

In conclusion, while it may be too late in the season to perform a full MIL on your pivot, it is not too late to start thinking about performing MIL’s on pivots in the fall after harvest and to fix some minor issues that will have significant impacts during the season. Some of these “minor” issues can include nozzles on guides, worn out rotators, blown off, leaking or stopped up nozzles, visible leaks, end gun setting and any other visible or similar problems. Any of these should be fixed as soon as you can so that there will not seasonal effects on your crop growth and yield. Anytime there are issues that are visible either via past or present satellite imagery (Google Earth or active satellites), real time imagery, by just visual inspection, or in yield maps, these problems have had a significant impact on your production and yields. For more in-depth information about pivot uniformity reach out to your local UGA Extension County Agent.