By Brian Mathis (TeeJet), Sarah Beth Thompson, Wesley Porter

Selecting the correct sprayer nozzle is critical for achieving effective pest and disease control while minimizing drift and maximizing coverage. Each crop and pesticide type—fungicide, insecticide, or herbicide—has unique requirements that influence nozzle selection. Hopefully, this post can help you work through the decision on which nozzle(s) to select to best suit your operation.

Understanding Nozzle Functionality

Sprayer nozzles determine:

- Droplet size (affecting coverage and drift)

- Extremely Fine to Ultra Coarse (See the ASABE standard below)

- Spray pattern (ensuring uniform application)

- Flat Fan, Twin Fan, Cone, Stream

- Flow rate and pressure compatibility

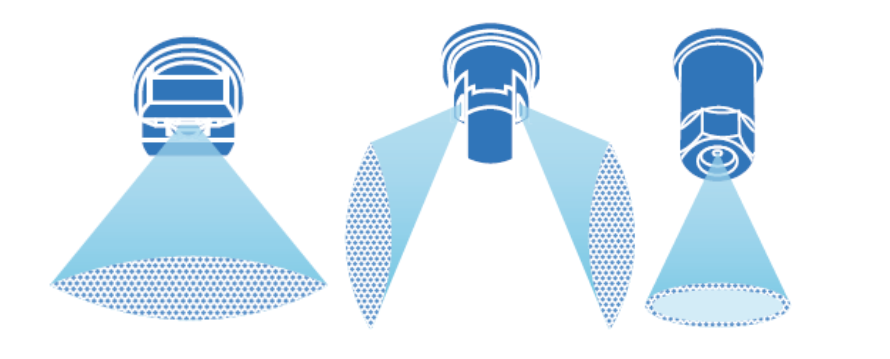

Spray Patterns

Spray patterns typically used for Effective Fungicide, Herbicide and Insecticide Applications are Flat Fan, Twin Flat Fan, and Cone spray tips:

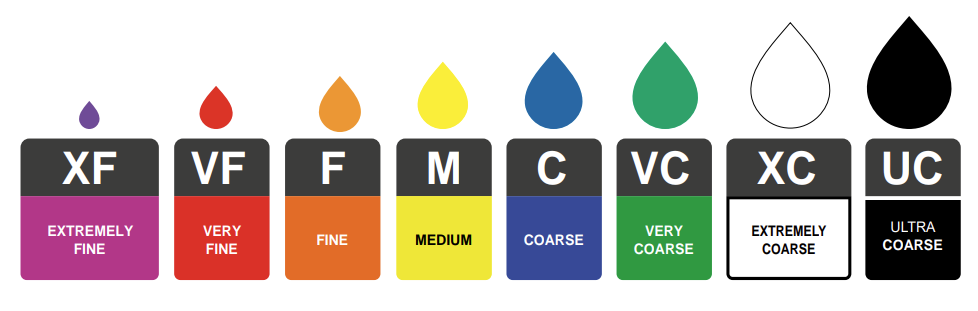

Droplet Classification Standards

The American Society of Agricultural and Biological Engineers (ASABE) classifies droplet sizes from extremely fine to ultra coarse. Most pesticide labels specify the required droplet size for optimal efficacy.

The Droplet Classification standards have been updated from the ASABE S572.1 to ASABE S572.3. Now, both the ISO 25358 and ASABE S572.3 standards use the same color code as described and shown below: (Notice the color change between Coarse and Very Coarse)

The International Organization for Standardization (ISO) initiated the development of an international droplet size classification standard, and in 2018, the ISO 25358 standard was published (ISO, 2018)⁴. The changes added to the new standard included the update of certain droplet size classification ranges to distribute the classification boundaries more effectively. The major changes happen on the C/VC, VC/XC, and XC/UC boundaries. Subsequently, the ASABE has aligned its standard with ISO 25358, resulting in the updated ASABE S572.3⁴ standard. In these new standards, the color-coding for most droplet size classes has been retained. The only exception is observed in the Coarse and Very Coarse classes, where there is an inversion of colors. In ASABE S572.2, Coarse was denoted in blue, and Very Coarse was represented in green. However, under the new ISO25358/ASABE S572.3, Coarse is now represented in green, while Very Coarse is represented in blue.

Nozzle Selection by Pesticide Type

Herbicides

- Contact herbicides (e.g., paraquat): require medium to coarse droplets for thorough leaf coverage

- Use Twin Flat Fan spray pattern tips to enhance coverage

- Systemic herbicides (e.g., glyphosate): prefer coarse to very coarse droplets to reduce drift and ensure uptake

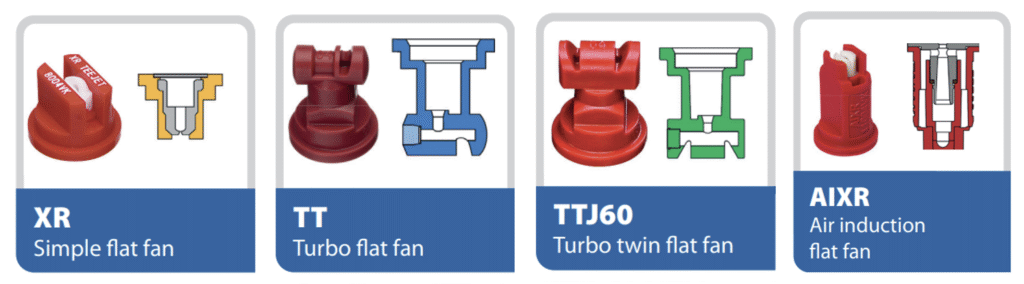

Recommended Nozzles:

- Flat Fan (XR, TT, TTJ60)

- Air induction (AI, AIXR, AITTJ) for drift reduction

- See below for a few examples

Fungicides

- Require medium droplets for canopy penetration and coverage, especially in dense crops like peanuts and soybeans. Pressures may be higher in some cases to increase canopy penetration, increasing drift potential.

Recommended Nozzles:

- Twin Flat Fan (TJ60, TTJ60)

- Air Induction Twin Flat Fan (AITTJ)

- Hollow cone for targeted applications

- See below for examples

Insecticides

- Often contact-based, medium droplets for effective coverage on foliage and pests.

Recommended Nozzles:

- Flat Fan or Twin Flat Fan for better leaf surface coverage (XR, TT, TTJ60)

- Air Induction (AIXR, AITTJ60)

- Hollow cone (TX)

- See below for a few examples

Crop-Specific Considerations

| Crop | Canopy Density | Preferred Droplet Size | Notes |

| Cotton | Moderate | Medium to Coarse | Use drift-reducing nozzles during bloom |

| Corn | Tall, upright | Coarse to Very Coarse | Use angled nozzles for ear zone targeting |

| Peanut | Dense, low canopy | Medium to Coarse | Tein fan nozzles improve penetration |

| Soybean | Moderate to dense | Medium | Adjust pressure for canopy stage |

Environmental and Equipment Factors

- Wind Speed: Use air induction to reduce drift. Monitor and try to spray at low wind speeds to reduce drift potential.

- Boom height: Maintain 18–24 inches above target for uniform coverage. A good rule of thumb is boom height above canopy should be equal to nozzle spacing.

- Pressure: Match with nozzle specs; higher pressure = finer droplets.

- Ground Speed: Ground speed should not exceed 10 to 12 mph.

Best Practices

- Always read the pesticide label for droplet size and application instructions.

- Use nozzle charts and selector tools (e.g., from TeeJet) to match flow rate and pressure.

- Regularly calibrate sprayers and check for proper flow rate and spray pattern integrity of each spray tip.

Conclusions

Effective pesticide application starts with the correct nozzle selection. By aligning nozzle type with pesticide mode of action, crop structure, and environmental conditions, growers can enhance efficacy, reduce waste, and protect surrounding ecosystems.